Application and Implications

This week we had to discuss the application of our final project. There are a few question pertaining to my project which I am going to answer.

This week we had to discuss the application of our final project. There are a few question pertaining to my project which I am going to answer.

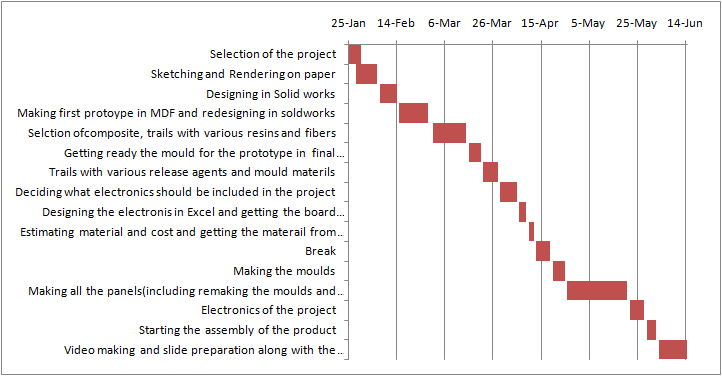

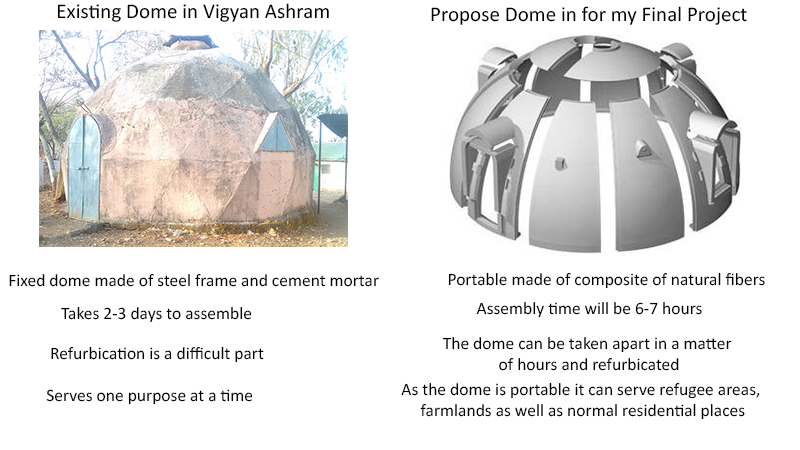

For my Final project I am making a Dome made out of natural composites. This is a very ambitious project for my Fab Lab. Domes have always been constructed at "Vigyan Ashram" since its inception in 1984, they have been made out of steel angles as a frame structure and sprayed with cement to cover the steel frame. Thus we have always constructed fixed dome houses, this time we want to make the dome house portable. The target customer will be the labourers working on fields or construction site who migrtae from places to places as per the job requirement.

My target customer moves to a new place every 7-8 months. Thus the material used to make his house needs to be light weight and capable of sustaining loads during the transportation along with the usual loads in a building. Also it will be a boon for the user if the building material is in a complete panel form rather than two or three components coming together. There are chances of misplacing and damaging the components especially small components and fixutures while transporting thus a complete panels with matrics and reinforcing fibers is required

Thus the dome will be a panelled dome made out of similar shaped panel repeated 16 times, thus the question of misplacing and damaging small compoents is solved

Vigyan Ashram has been promoting sustainable and eco friendly way of living, thus sticking to this principle we challenged ourselves to make use of locally available natural material as far as possible.

Lightweight material meant that cement was out of question and manufacturing cement is not an environmental friendly practice, thus we are looking at resin as major part of the building material. Glass Fibre Reinforced Plastic has been finding a lot of application in the construction and manufacturing industry, we wanted to decided to try this material but with a little modification.

The glass fibre is not environmental friendly and it causes a lot of hazard if not handled properly, machining the glass fibre reinforced plastic and inhaling it causes lung diseases. Thus Thus we are looking to replace the glass fibre totally from this composites

There a lot of natural fibers readily available around my lab such as burlap, bamboo, cotton, sorgum etc. I will be experimenting with this throughout this project to find a mix of a natural composite suitable for a building material.

Thus the natural fibers will be available locally as far as the question of resin goes I am using General purpose Polyester resin I will have to purchase it from Pune

Neil suggested me some bio resins called super sap made by Entrophy resin, but the resin is very expensive as a building material, it costs around 5000Rs for 2 litre of resin.

Along with composite building material I am also planning to put motion sensing lights in the house, This light will be made in FabLab using 3d printing and electronic production.

Geodesic domes have been constructed throughout the world and in Vigyan Ashram for a long time, But the dome I am doing is a panelled dome and the panels are shaped in trapezoidal plates instead of traingular.This I found very unique about my project and I did not find much work like this on the internet.

I have dound this project been done on a commercial level in the state of GUJRAT, the link is here

They are using Fiber Reinforced Plastic and styrofoam as an insulation, I am yet to find a project which is exactly same as mine.

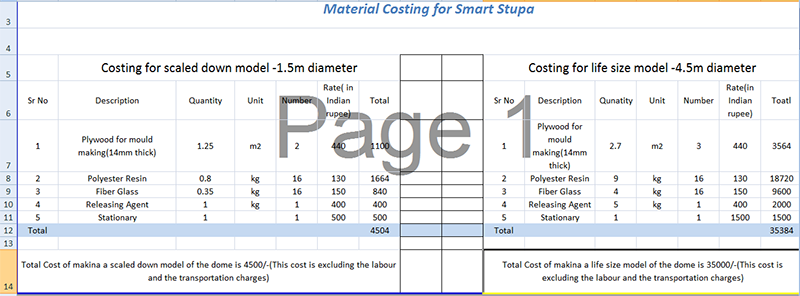

A similar kind of a prefabricated dome is being made in gujrat, the selling cost of such a dome with the same floor area is around 45000/-, thus I want to be somewhere near that number. I have made a cost estimation for my project, the numbers may change according to the cost of material locally.

Download the excel sheet from here

Dome Panels- The dome panels will be made of polyester resin and natural fibers, they will be casted in a mould made using ShopBot machine.

The enclosure of the lightings for the house will be 3d printed

The electronics will be made using in house milling machine and components will be from the FabLab Inventory

The propose furniture will be made using laser engraver and ShopBot machine.

What questions need to be answered? I am pretty clear abouth my project its just the response of the user that I am worried about because a residencial place is traditionally and angular structure I am not sure if the dome shape will be excepted by the user or not. Also I am worried about the design and the arrangement of the doors and the windows, I am confuses wether to make the dome well insulated or make it good ventilated.